How to get a prototype of a product made

Home » Free Imaging » How to get a prototype of a product madeHow to get a prototype of a product made

How To Get A Prototype Of A Product Made. Finally once you actually do get your first prototype made the process doesnt end there. Give yourself permission to experiment. To take your napkin drawing to the next level Engineer. And for larger numbers of prototypes in actual production materials for moldablity testing or for low volume production rapid injection molding is the perfect choice 4.

How To Get A Prototype Product Made From flynn-product-design.com

How To Get A Prototype Product Made From flynn-product-design.com

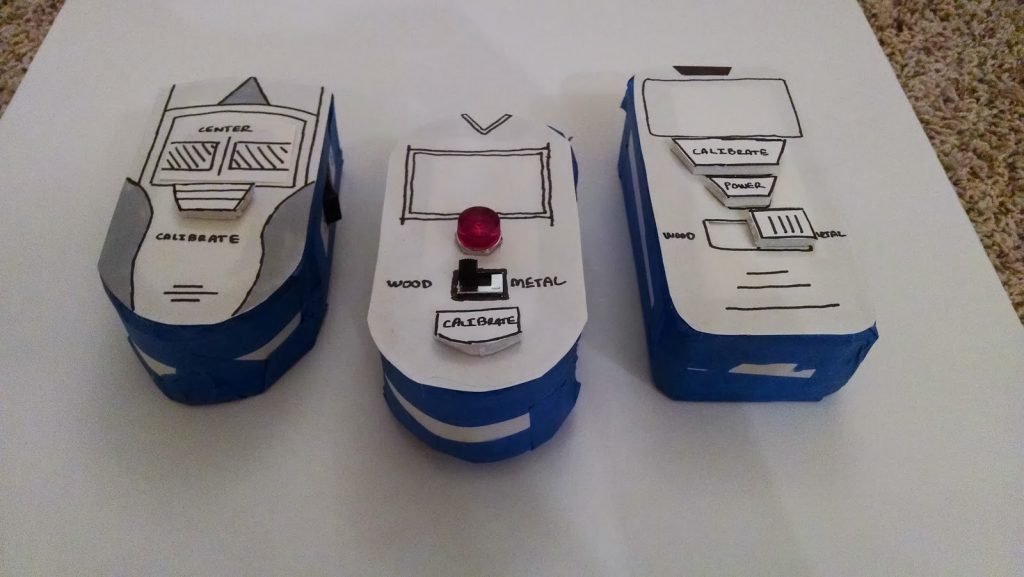

You could ask friends or family to invest in your idea but these days you can also do things like crowdfunding on sites like Kickstarter to get the funding and support you need to get your idea to market. It is likely that you will end up with an entire sketch book of designs as your creative energies flow out onto paper. It might be a good idea to buy an existing product and disassemble it. The first step in creating your initial product prototype is to create a sketch of your design both as a complete unit and separately with the individual components. Of course this advice is applicable only in case you are not creating something revolutionary from scratch but frankly such inventions are rare. Making a prototype by hand is a great way to start bringing your product to life.

To take your napkin drawing to the next level Engineer.

You could ask friends or family to invest in your idea but these days you can also do things like crowdfunding on sites like Kickstarter to get the funding and support you need to get your idea to market. How to Make a Prototype for Your New Product Design. Remember that you are not trying to. Of course in order to make a prototype you are going to likely need funding as not everyone is independently wealthy. For one thing in the early stages of creating your prototype. Once the design is finalised you need to get prototypes made that look and operate as close as possible to the finished product.

Source: wikihow.com

Source: wikihow.com

The first step toward turning your idea into reality is getting it down on paper. And if you cant do it yourself there are plenty of others willing and. The method for creating the prototype depends on what type of invention you have. Prototyping is a two-pronged process. It provides excellent appearance qualities replicates materials exactly and can appear indistinguishable from the real thing.

Source: waykenrm.com

Source: waykenrm.com

In some cases you may even be able to do it yourself. Refine Your Prototype to Perfection This stage is the most painful and time-consuming one of all. Likely youre going to have to re-work the product and repeat the prototyping. To start with its usually a good idea to check how other similar products are made. Prototyping is a two-pronged process.

Source: wikihow.com

Source: wikihow.com

Then you combine and make one final sketch. Here are some key tips for building the first prototype of an invention. To make your napkin design come to life. Of course in order to make a prototype you are going to likely need funding as not everyone is independently wealthy. Create a Concept Sketch.

Source: flynn-product-design.com

Source: flynn-product-design.com

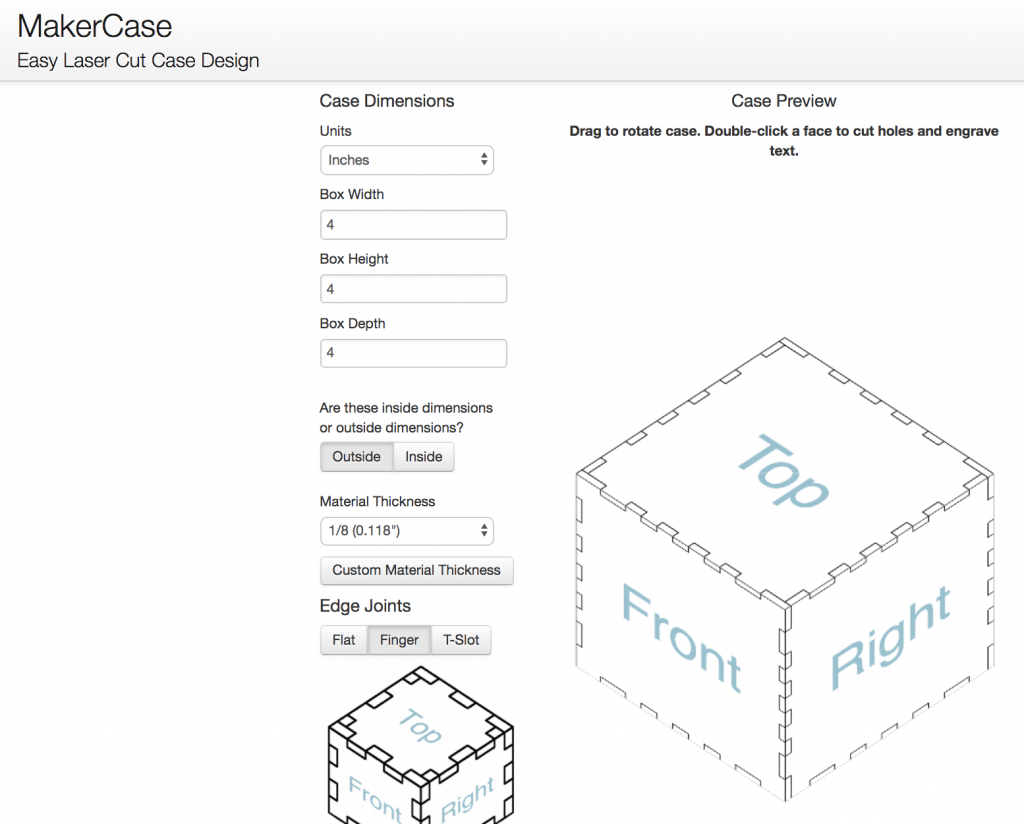

The method for creating the prototype depends on what type of invention you have. It is likely that you will end up with an entire sketch book of designs as your creative energies flow out onto paper. For one thing in the early stages of creating your prototype. As a result when it comes to creating a prototype of your product you should assemble the following teammates. You will need to supply the prototype manufacturer with an outline CAD data and detailed drawings of your product idea.

Source: athgo.org

Source: athgo.org

Then you are going to sit back down with the designer after youve completed the sketches and pick out which functions look and feel that you like to each one of the sketches. Refine Your Prototype to Perfection This stage is the most painful and time-consuming one of all. The product development process starts with realizing the Product Design that you have already or developed with us. Maybe you realized that it. Then as you progress in the prototyping process its about examining the strengths and weaknesses of your product by comparing it to what else is out there.

Source: ponoko.com

Source: ponoko.com

To take your napkin drawing to the next level Engineer. Here are four steps to get your first prototype built so you can turn your idea into a patented profitable product. The first step in creating your initial product prototype is to create a sketch of your design both as a complete unit and separately with the individual components. We review the physical design to a granular level testing the functionality and user experience. Of course this advice is applicable only in case you are not creating something revolutionary from scratch but frankly such inventions are rare.

Source: sparkinnovations.com

Source: sparkinnovations.com

Remember that you are not trying to. The first step toward turning your idea into reality is getting it down on paper. To take your napkin drawing to the next level Engineer. The method for creating the prototype depends on what type of invention you have. A virtual prototype shows your products scale and how it will actually function via virtual simulation.

Source: ponoko.com

Source: ponoko.com

Create a Concept Sketch. It is likely that you will end up with an entire sketch book of designs as your creative energies flow out onto paper. Of course in order to make a prototype you are going to likely need funding as not everyone is independently wealthy. Here are some key tips for building the first prototype of an invention. Remember that you are not trying to.

Source: wikihow.com

Source: wikihow.com

For example your invention may be made of fabric or soft materials. As a result when it comes to creating a prototype of your product you should assemble the following teammates. The product development process starts with realizing the Product Design that you have already or developed with us. To make your napkin design come to life. Finally once you actually do get your first prototype made the process doesnt end there.

Source: wikihow.com

Source: wikihow.com

The first step in creating your initial product prototype is to create a sketch of your design both as a complete unit and separately with the individual components. And for larger numbers of prototypes in actual production materials for moldablity testing or for low volume production rapid injection molding is the perfect choice 4. Drawings will need to be converted into 3D CAD which has cost implications. Likely youre going to have to re-work the product and repeat the prototyping. Then as you progress in the prototyping process its about examining the strengths and weaknesses of your product by comparing it to what else is out there.

Source: youtube.com

Source: youtube.com

We review the physical design to a granular level testing the functionality and user experience. It provides excellent appearance qualities replicates materials exactly and can appear indistinguishable from the real thing. And for larger numbers of prototypes in actual production materials for moldablity testing or for low volume production rapid injection molding is the perfect choice 4. The first step in creating your initial product prototype is to create a sketch of your design both as a complete unit and separately with the individual components. We review the physical design to a granular level testing the functionality and user experience.

Source: ponoko.com

Source: ponoko.com

To start with its usually a good idea to check how other similar products are made. Of course this advice is applicable only in case you are not creating something revolutionary from scratch but frankly such inventions are rare. Finally once you actually do get your first prototype made the process doesnt end there. Then you are going to sit back down with the designer after youve completed the sketches and pick out which functions look and feel that you like to each one of the sketches. Remember there are no rules.

Source: unicorn-insights.com

Source: unicorn-insights.com

Remember there are no rules. While it is possible to use a digital drawing program for this step it may be more efficient to start on paper first. Remember that you are not trying to. Here are some key tips for building the first prototype of an invention. Maybe you realized that it.

Source: ponoko.com

Source: ponoko.com

Prototyping is a two-pronged process. Here are four steps to get your first prototype built so you can turn your idea into a patented profitable product. Being as detailed as possible will make the next steps in the process easier for you and the design and manufacturing professionals. Look around the house and select materials. To make your napkin design come to life.

Source: unicorn-insights.com

Source: unicorn-insights.com

Finally once you actually do get your first prototype made the process doesnt end there. Drawings will need to be converted into 3D CAD which has cost implications. The method for creating the prototype depends on what type of invention you have. Then you are going to sit back down with the designer after youve completed the sketches and pick out which functions look and feel that you like to each one of the sketches. Maybe you realized that it.

If you find this site convienient, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title how to get a prototype of a product made by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.