Rapid prototyping process

Home » Free Imaging » Rapid prototyping processRapid prototyping process

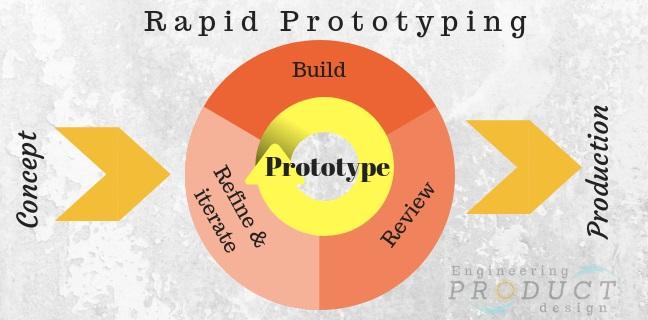

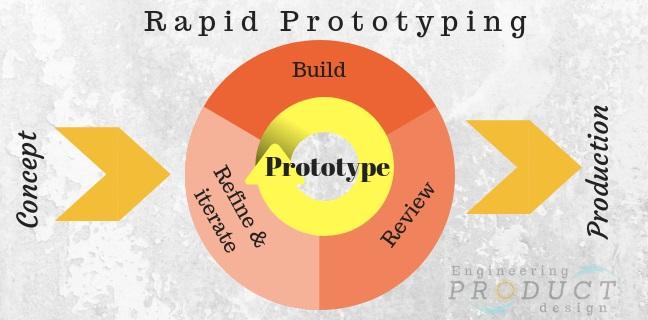

Rapid Prototyping Process. Rapid prototyping is an agile strategy used throughout the product development process. In contrast most machining processes are. Rapid prototyping is an additive process combining layers of paper wax or plastic to create a solid object. Rapid Prototyping will help you capture the issues early in the design process and hence save time and money.

What Is Rapid Prototyping Protyping Techniques Benefits And Limitations From engineeringproductdesign.com

What Is Rapid Prototyping Protyping Techniques Benefits And Limitations From engineeringproductdesign.com

2Rapid Prototyping facilitates collaboration. Prototyping testing and refining. During this process a computer-controlled UV light laser traces each 2D slice of a part on the build platform curing a liquid photopolymer resin. In the process of user interface design rapid prototyping refers to the process of designers quickly creating prototypes and simulating the future state of a website or software system. The rapid prototyping process involves three simple steps. Its an indefinite loop which should be utilized over and over until the team is satisfied with their validated approach.

The creation of the part model or assembly is usually completed using additive manufacturing or more commonly known as 3D printing.

Rapid Prototyping RP can be defined as a group of techniques used to quickly fabricate a scale model of a part or assembly using three-dimensional computer aided design CAD data. In the process of user interface design rapid prototyping refers to the process of designers quickly creating prototypes and simulating the future state of a website or software system. Its use is generally industrial and prior to making several series of products. The rapid prototyping process involves three simple steps. In contrast most machining processes are. The first methods for rapid prototyping became available in the late 1980s and were used to produce models and.

Source: researchgate.net

Source: researchgate.net

Some prototyping processes use traditional manufacturing methods to produce prototypes while other technologies have more recently emerged. By this reliability of product can be increased investment of time and money is less risky. Stereolithography SLA is the tried-and-true rapid prototyping choice for many design and engineering teams. In the manufacturing world rapid prototyping is much quicker than traditional prototyping which may take months or even years. Rapid Prototyping is an iterative process used to visualize what a website or an application will look like in order to get feedback and validation from users stakeholders developers and designers.

Source: youtube.com

Source: youtube.com

In the manufacturing world rapid prototyping is much quicker than traditional prototyping which may take months or even years. Some prototyping processes use traditional manufacturing methods to produce prototypes while other technologies have more recently emerged. The first methods for rapid prototyping became available in the late 1980s and were used to produce models and. Each completed layer adheres to the next and the process is repeated until a full part. Rapid prototyping is the fast fabrication of a physical part model or assembly using 3D computer aided design CAD.

Source: lawrence-najjar.com

Source: lawrence-najjar.com

Rapid prototyping is all about getting an idea in front of users collecting feedback and quickly refining and iterating your idea based on that feedback. Its use is generally industrial and prior to making several series of products. Prototypes are convenient for users investors developers and designers to communicate and validate their design ideas. In the process of user interface design rapid prototyping refers to the process of designers quickly creating prototypes and simulating the future state of a website or software system. Rapid prototyping is all about getting an idea in front of users collecting feedback and quickly refining and iterating your idea based on that feedback.

Source: prostech.vn

Source: prostech.vn

Prototypes are convenient for users investors developers and designers to communicate and validate their design ideas. Rapid prototyping is the fast fabrication of a physical part model or assembly using 3D computer aided design CAD. Construction of the part or assembly is usually done using 3D printing or additive layer manufacturing technology. Subtractive Where carving through a block of material to create the desired shape by milling grinding or turning. Its use is generally industrial and prior to making several series of products.

Source: shopify.ca

Source: shopify.ca

Some prototyping processes use traditional manufacturing methods to produce prototypes while other technologies have more recently emerged. Rapid prototyping is an additive process combining layers of paper wax or plastic to create a solid object. Its an indefinite loop which should be utilized over and over until the team is satisfied with their validated approach. While additive manufacturing is the most common rapid prototyping process other more conventional methods can be used to create prototypes. Rapid Prototyping is an iterative process used to visualize what a website or an application will look like in order to get feedback and validation from users stakeholders developers and designers.

Source: en.wikiversity.org

Source: en.wikiversity.org

Rapid prototyping is all about getting an idea in front of users collecting feedback and quickly refining and iterating your idea based on that feedback. Collaboration with different people leads to higher chances of building solution and validating it faster. Rapid Prototyping will help you capture the issues early in the design process and hence save time and money. But what makes it rapid compared to standard prototyping. Rapid prototyping is all about getting an idea in front of users collecting feedback and quickly refining and iterating your idea based on that feedback.

Source: lumitex.com

Source: lumitex.com

Each completed layer adheres to the next and the process is repeated until a full part. RP is the oldest application of the process and the process owes its invention to RP. In the manufacturing world rapid prototyping is much quicker than traditional prototyping which may take months or even years. It is used for making prototypes for engine block architectural model wind tunnel model medical model of a defective organ and several prototypes for visual fit and form test. Rapid prototyping is the fast fabrication of a physical part model or assembly using 3D computer aided design CAD.

Source: theproductmanager.com

Source: theproductmanager.com

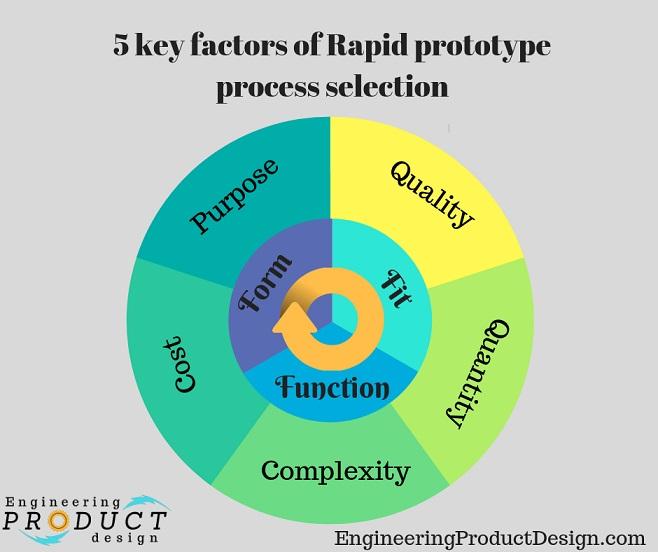

Some prototyping processes use traditional manufacturing methods to produce prototypes while other technologies have more recently emerged. Prototypes are convenient for users investors developers and designers to communicate and validate their design ideas. RPT and Rapid Manufacturing RM offers great potential for producing models and parts. With this approach 3-dimensional prototypes of a product or feature are created and tested to optimize characteristics like shape size and overall usability. Prototyping The team creates an initial prototype.

Source: engineeringproductdesign.com

Source: engineeringproductdesign.com

Rapid prototyping is all about getting an idea in front of users collecting feedback and quickly refining and iterating your idea based on that feedback. Rapid prototyping is an additive process combining layers of paper wax or plastic to create a solid object. Prototypes are convenient for users investors developers and designers to communicate and validate their design ideas. During this process a computer-controlled UV light laser traces each 2D slice of a part on the build platform curing a liquid photopolymer resin. Stereolithography SLA is the tried-and-true rapid prototyping choice for many design and engineering teams.

Source: researchgate.net

Source: researchgate.net

The rapid prototyping process includes three steps. So what exactly is the rapid prototyping approach. Prototyping The team creates an initial prototype. Designers go through these stages in order improving their solutions based on the prototype testing results and the feedback they received from users. 2Rapid Prototyping facilitates collaboration.

Source: engineeringproductdesign.com

Source: engineeringproductdesign.com

The creation of the part model or assembly is usually completed using additive manufacturing or more commonly known as 3D printing. With this approach 3-dimensional prototypes of a product or feature are created and tested to optimize characteristics like shape size and overall usability. This is a visual representation of the design specifications as set. Its an indefinite loop which should be utilized over and over until the team is satisfied with their validated approach. 2Rapid Prototyping facilitates collaboration.

Source: sciencedirect.com

Source: sciencedirect.com

So what exactly is the rapid prototyping approach. Prototyping The team creates an initial prototype. Subtractive Where carving through a block of material to create the desired shape by milling grinding or turning. Rapid prototyping is all about getting an idea in front of users collecting feedback and quickly refining and iterating your idea based on that feedback. Collaboration with different people leads to higher chances of building solution and validating it faster.

Source: xd.adobe.com

Source: xd.adobe.com

Collaboration with different people leads to higher chances of building solution and validating it faster. Rapid Prototyping is an iterative process used to visualize what a website or an application will look like in order to get feedback and validation from users stakeholders developers and designers. The first methods for rapid prototyping became available in the late 1980s and were used to produce models and. During this process a computer-controlled UV light laser traces each 2D slice of a part on the build platform curing a liquid photopolymer resin. Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design data.

Source: uxpin.com

Source: uxpin.com

Rapid Prototyping RP can be defined as a group of techniques used to quickly fabricate a scale model of a part or assembly using three-dimensional computer aided design CAD data. RP is the oldest application of the process and the process owes its invention to RP. Rapid prototyping is an agile strategy used throughout the product development process. Many rapid prototyping processes are available to todays product design teams. It is used for making prototypes for engine block architectural model wind tunnel model medical model of a defective organ and several prototypes for visual fit and form test.

Source: protolabs.com

Source: protolabs.com

Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design data. In the process of user interface design rapid prototyping refers to the process of designers quickly creating prototypes and simulating the future state of a website or software system. In digital design rapid prototyping is the process of iteratively mocking up an interface and validating it with users stakeholders and even your teammates. Kumar in Comprehensive Materials Processing 2014. RPT can automatically construct physical models CAD data.

If you find this site good, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title rapid prototyping process by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.